Take away 3 points

- Fleet optimization must take into account not only costs but also environmental considerations

- Companies often struggle with effective collection and use of data and must turn to digital solutions to gain full understanding of their fleets

- A holistic data approach allows for a significant increase in fleet sustainability and cost effectiveness

Sustainable fleet management is becoming an increasingly complex issue. Managers must take into consideration not only the costs pertinent to operating the corporate fleet but also bear in mind a large number of business, environmental and social factors. In a dynamically changing environment, it is necessary to have access to a complete set of information derived from various data sources to make the right decisions in executing the sustainability strategy. OviDrive offers a comprehensive system that will collect, process, and present data allowing for easy identification of targets and implementation steps.

Identifying the necessary data

The advancement of modern approaches to data collection allows for access to an ever increasing amount of information. However, companies struggle to identify the necessary information, keep track of it, and put it to meaningful use without an appropriate approach to data. Manual analyses are becoming more complex and time consuming. This is why companies turn to digital systems that assemble data and provide stakeholders with the information needed to understand it. By utilizing primary data sources, vendor data, and information on user attitudes and behaviors, and reusing existing data, these systems can increase the efficiency of the analysis allowing decision- makers to make increasingly informed choices on the fleet, asset replacement, and optimization and create value to stakeholders very fast and early on [1].

Legislative changes driving new technologies

Fleet optimization must take into consideration a large spectrum of factors. Financial, legal, environmental, and behavioral concerns must all be considered when developing and delivering the company’s sustainability strategy. Various policies are being introduced that will influence the costs of operating corporate fleets and impact the structure of their assets and how they are being used. For example, The European Union is currently introducing several policies that will significantly influence fleet optimization decisions in the coming years. The recently announced ambitious “Fit for 55” Strategy assumes a reduction of CO2 emissions by 55% by 2030 and a de facto ban on sales of non- electric vehicles by 2035. The proliferation of Carbon Tax and Cap and Trade policies used to reduce CO2 emissions will also force a reduction in the use of fossil fuel vehicles or significantly drive up their costs of operation. On the other hand, these measures lead to the development of new, innovative solutions in transportation to make it more sustainable, which further influences fleet decisions. Adopting new technology can reduce maintenance and operation costs, thereby making companies more competitive [2]. This phenomenon requires decision- makers to make the most of available data.

Including environmental concerns in fleet optimization

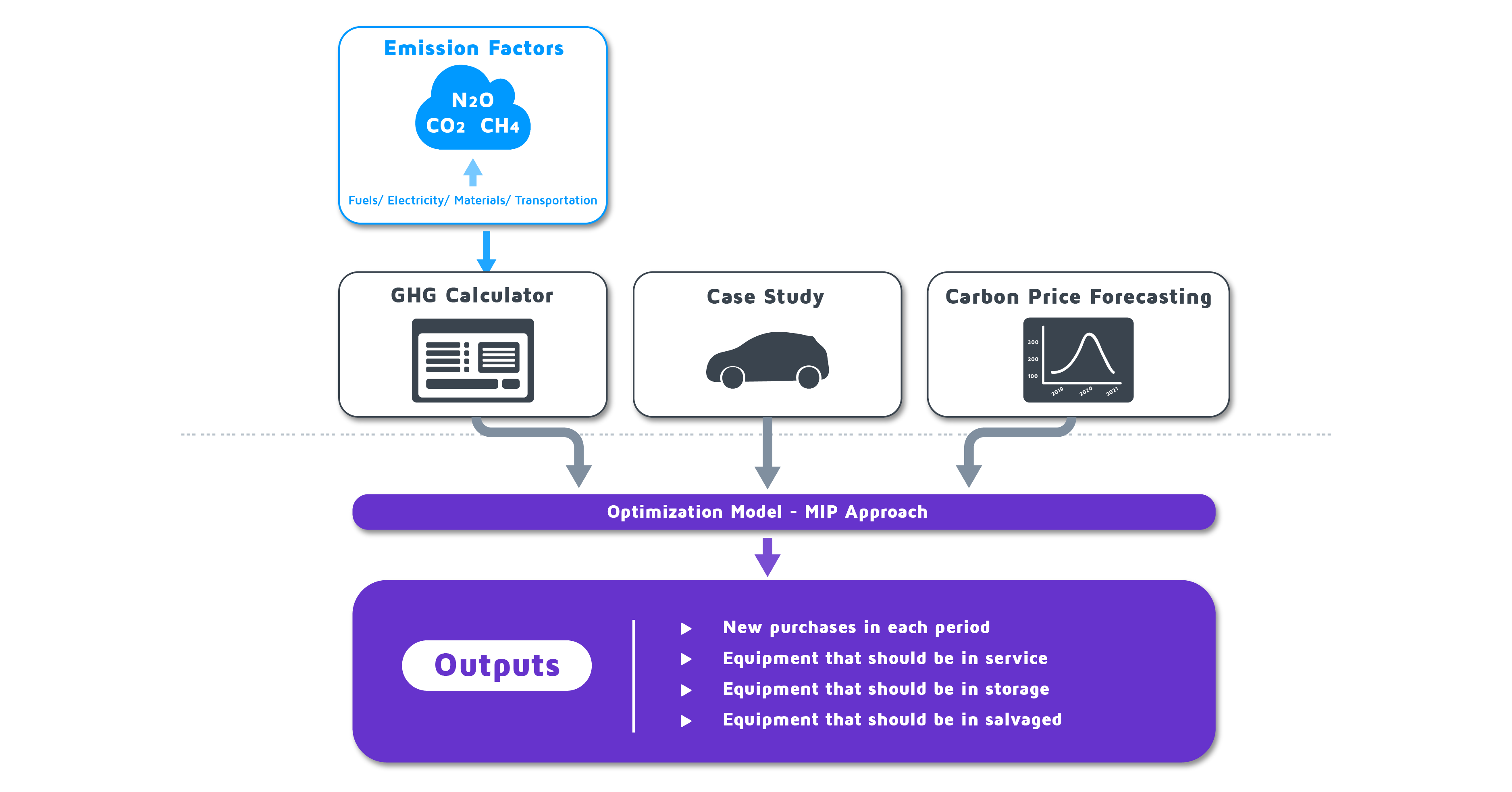

There is a minimal number of models that have been developed to help with fleet optimization decisions. Abdi and Taghipour suggest a fleet optimization model, which simultaneously minimizes the total ownership cost and the total greenhouse gas emissions caused by the fleet. To consider the economic and environmental factors, the authors include: (a) purchasing new assets, operation and maintenance of in-use assets, (b) holding in-storage assets, and (c) salvaging assets. The model also takes into consideration greenhouse gas emission cap and the budgetary contains. Its outputs include the optimal decision on the mix of assets that should be in use, in storage, and salvaged in each period. Additionally, it determines how many new assets should be purchased and added to the fleet in each period [3]. The model utilizes the mixed-integer programming (MIP) formulation developed by Büyüktahtakın and Hartman that takes into consideration that technologically improved assets have higher capacity than assets purchased earlier [4]. The model indicates that economic costs cannot be the only factor that should be considered in making fleet- related decisions as environmental burden accounts for 13 percent of the total optimum cost of the fleet [3].

Managing data- driven knowledge in organizations for better decision making

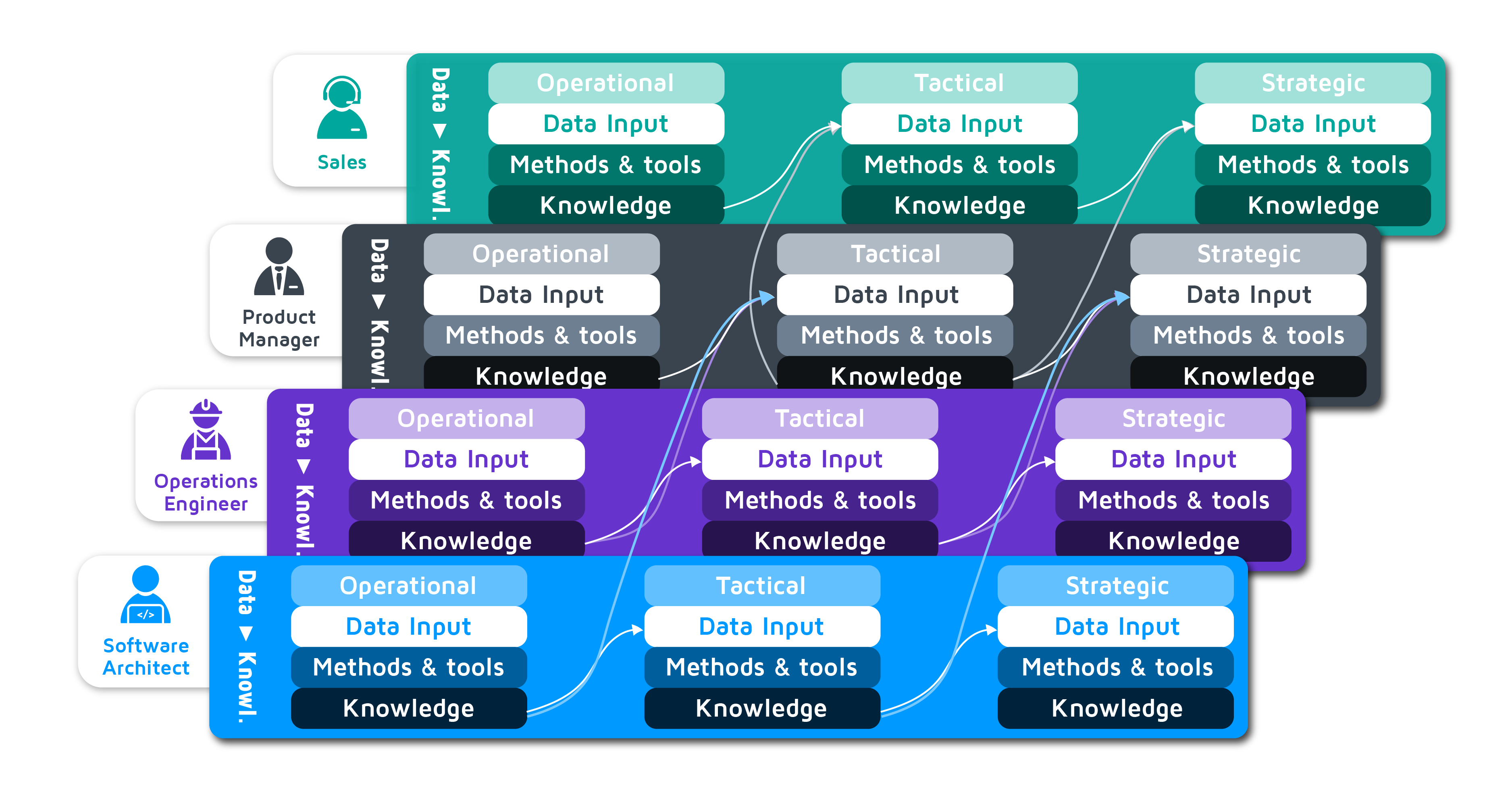

The model presented above allows for using fleet data and information on the cost of CO2 emissions to decide on fleet optimization. It does not, however, explain how to manage this knowledge in order to facilitate decision making. A study by a team of German and Swedish researchers explores that issue in more detail. The study investigates how to support decision making by providing relevant data-based insights related to a specific area of responsibility, e.g., fleet management. It concludes that the information needs of stakeholders are often associated with a limited batch of data sources and should be specified in stages. Stakeholders often benefit from sharing and reusing existing items among themselves in later phases. Specifically, the model identifies three types of reusable items: (1) Data and knowledge, consisting of aggregated data, components, and knowledge generated during the analysis (2) tools and methods that can be used in different levels in order to achieve specific tasks and (3) concepts. The authors propose a generic model that enables continuous and efficient operational, tactical , and strategic measurements for various stakeholders [1]. Therefore, data must be collected and stored in a cloud-based, easy to access system that allows for information to be easily shared, used, and reused by various stakeholders within the organization. Both studies correlate with OviDrive’s estimates that switching to a sustainability-driven digital fleet management system may reduce total ownership costs by up to 15 percent.

Using digital transformation for better sustainability

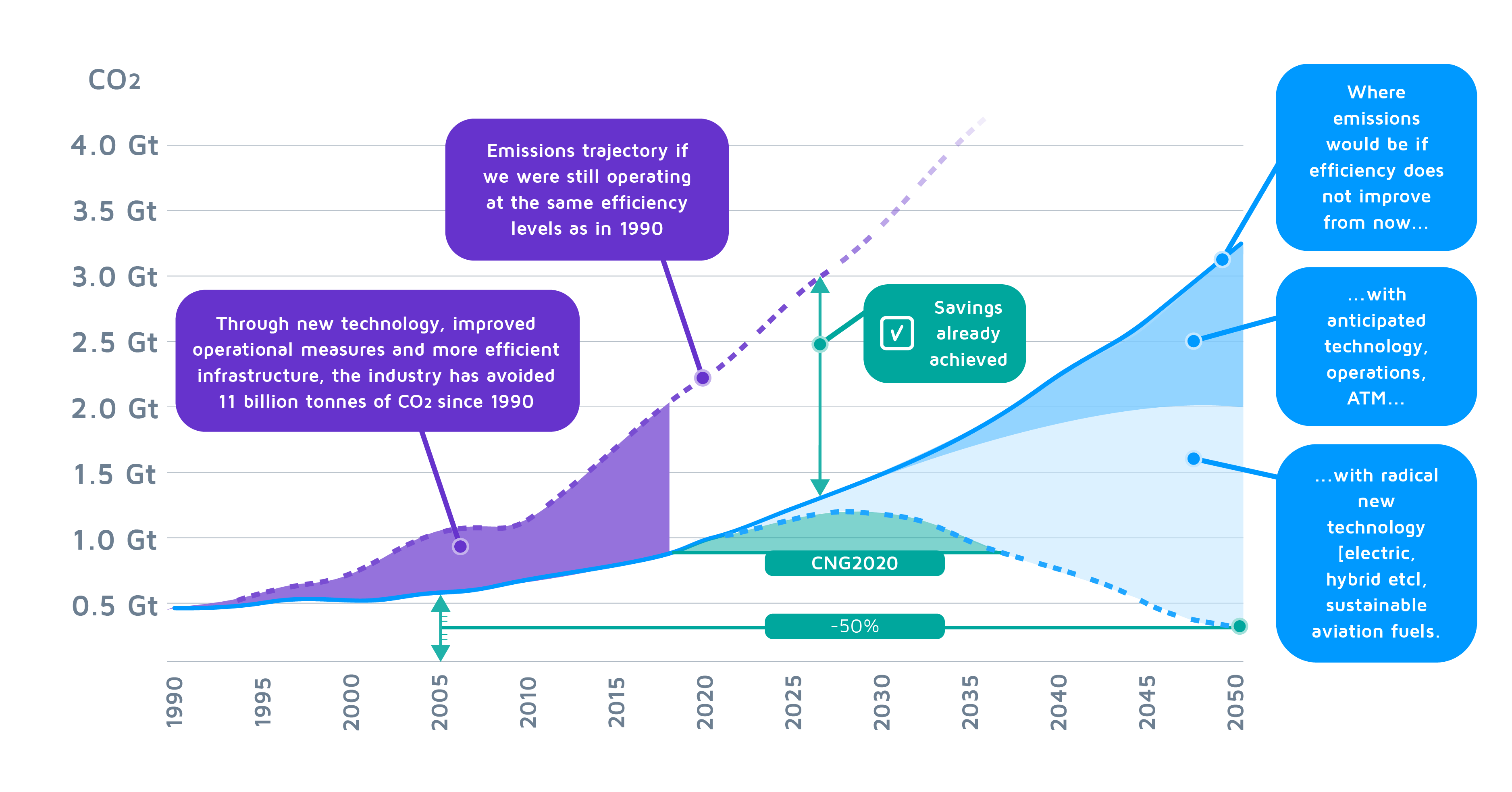

Fleet optimization towards sustainability is no longer possible without using digital technologies and use of automatically assembled data. The digital transformation of the industry fosters sustainability through increasing efficiency and the adoption of newer and cleaner policies. A study of IATA (International Air Transport Association) indicated that automated information management within the industry has a significant impact on its environmental sustainability and cost reduction. It is estimated that the aviation industry’s introduction of new technologies, improved operational measures, and a more efficient infrastructure allowed to avoid 11 billion tons of CO2 emissions since 1990. It was also indicated that enabling, promoting, and reinforcing engagement with innovative solutions within the organization bring additional perspective about process variability, thus contributing to knowledge within the company and improves the system overall [5].

Another study on the digitalization of industrial machines indicates that the collection and analysis of operational data significantly reduces fuel consumption and increases the productivity of vehicles. The results confirm the importance of a set of factors, including aspects related to the vehicles’ travels, drivers, operations, workload spectra, and contextual factors, such as industry and country. The study also suggests that the critical conditioning factors interact in a non-linear and non-additive way. This means that addressing one factor at a time might not provide optimal fuel consumption, and instead, all elements need to be addressed simultaneously as a system [6]. It cannot be done manually and therefore requires automated and holistic data collection and analysis.

Conclusion

Fleet optimization depends on a large number of factors and data. These factors are interconnected and need to be addressed in a holistic manner in order to drive the fleet towards a more sustainable model. There is clear evidence that using data via digital solutions in fleet management must be coupled with the appropriate strategy and implementation steps. This approach, applied by OviDrive, will positively affect cost effectiveness, drive efficiency, and reduce environmental impact.

References

- Figalist, Iris, Christoph Elsner, Jan Bosch, and Helena Holmström Olsson. "Fast and curious: A model for building efficient monitoring-and decision-making frameworks based on quantitative data." Information and Software Technology 132 (2021): 106458.

- Chen, You-hua, Chan Wang, Pu-yan Nie, and Zi-rui Chen. "A clean innovation comparison between carbon tax and cap-and-trade system." Energy Strategy Reviews 29 (2020): 100483.

- Abdi, Abdollah, and Sharareh Taghipour. "An optimization model for fleet management with economic and environmental considerations, under a cap-and-trade market." Journal of Cleaner Production 204 (2018): 130-143.

- Büyüktahtakın, İ. Esra, and Joseph C. Hartman. "A mixed-integer programming approach to the parallel replacement problem under technological change." International Journal of Production Research 54, no. 3 (2016): 680-695. As cited in [3].

- Ordieres-Meré, Joaquín, Tomas Prieto Remon, and Jesús Rubio. "Digitalization: An opportunity for contributing to sustainability from knowledge creation." Sustainability 12, no. 4 (2020): 1460.

- Pashkevich, Natallia, Darek Haftor, Mikael Karlsson, and Soumitra Chowdhury. "Sustainability through the Digitalization of Industrial Machines: Complementary Factors of Fuel Consumption and Productivity for Forklifts with Sensors." Sustainability 11, no. 23 (2019): 6708.